Who we are and what we do

Originally established as a family-run business in Milan in 1933, Italian Olmi SpA moved to Suisio in 1962 where the company has grown to become a leading business and an approved manufacturer by process licensees of shell-and-tube heat exchangers and air coolers for critical applications in the petrochemical, power and oil and gas industries.

In 2010, the company was acquired by the Swedish group Alfa Laval, a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling.

More information

History of Olmi

About Alfa Laval

All Alfa Laval Olmi heat exchangers are unique. Each one is the result of a close cooperation between our design team and our customers’ engineers. Choosing Alfa Laval gives you full access to our team of thermal, mechanical and metallurgical experts and all their application and design knowledge.

Engineering expertise

Choosing Alfa Laval Olmi means you have the full backing of our application, thermal and mechanical design experts who will support you from the initial idea stage and advise you on a wide range of topics. They are used to handling the most complex heat exchanger design challenges, and in close cooperation with our welding and manufacturing teams they ensure you get a solution that offers maximum reliability, high performance and low investment costs.

Metallurgy

Material selection is a key stage when designing a heat exchanger operating at high temperatures and pressures. Choosing the right material is essential for reliable operation, long life span and low service costs. Based on your specific conditions, our metallurgy experts recommend materials that offer an optimum balance between CAPEX and OPEX.

Built to last

The quality and operational reliability of our products is our first priority. We know that even a minor imperfection in a weld joint in a high-pressure heat exchanger can cause costly breakdowns. When you install one of our heat exchangers you can rest assured that nothing has been left to chance and that every detail is of the highest quality.

All Alfa Laval Olmi heat exchangers are built and thoroughly tested in our own workshop to ensure their quality. This gives us tight control over the entire process form design to installation, and ensure the highest possible product reliability.

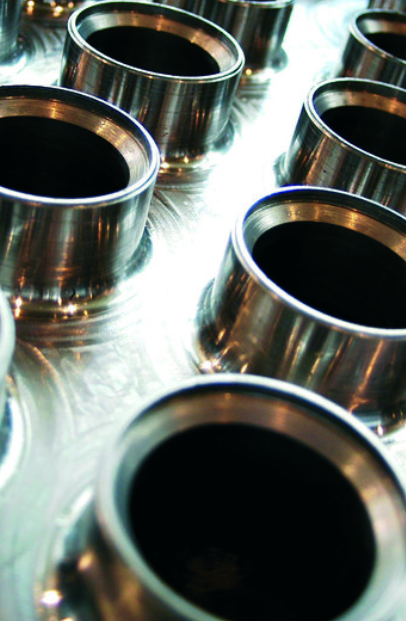

Welding

Welding is one of our core competencies and we continuously invest in staff training, certifications and new welding technology to ensure the highest weld quality.

Testing

Every heat exchanger that leaves our workshop has been thoroughly tested using a range of non-destructive tests, such as ultrasonic NDE, x-ray/gamma ray tests, hydro tests, helium and dye penetrant tests. Our inspectors are certified according to NDE Level II and III according to SNT TC1A and EN9712.

Capacity for large units

In our 65,000 m2 workshop we have the capacity to manufacture large-scale heat exchangers.